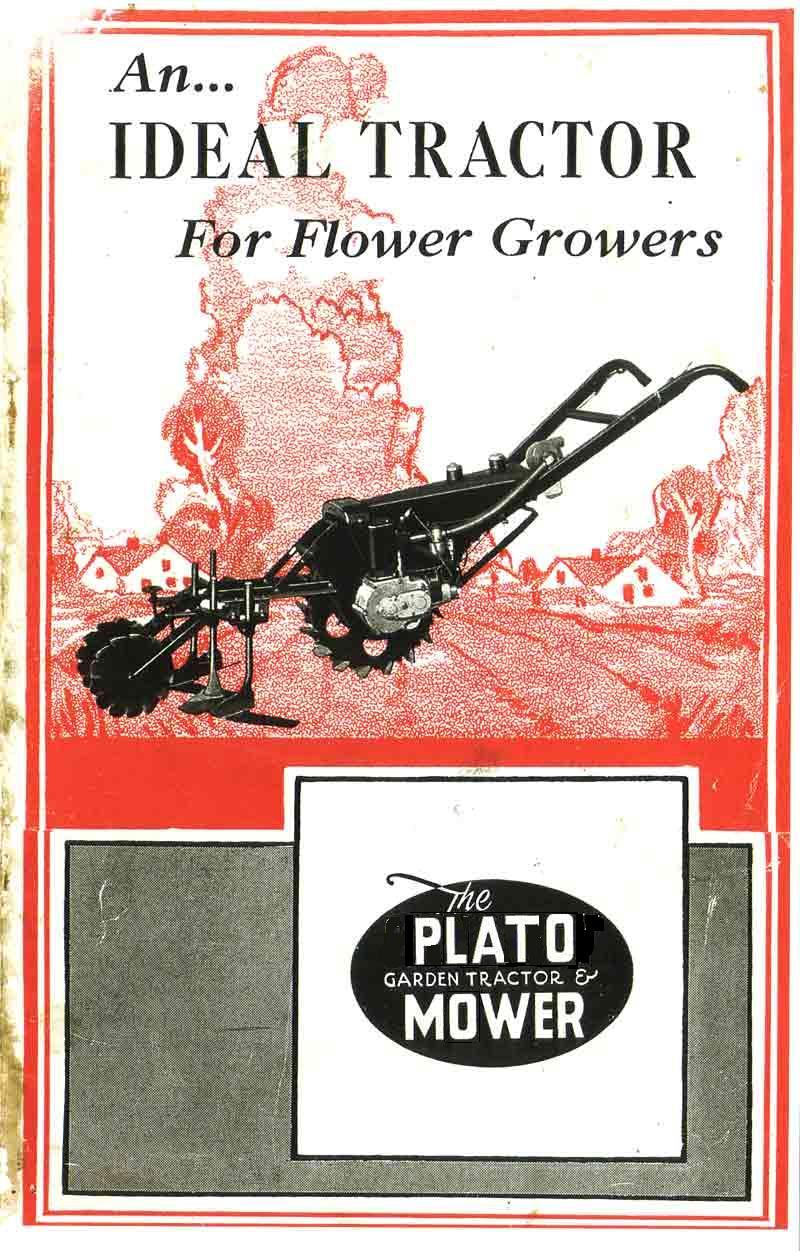

Scienticians Create Cybernetic Tractor

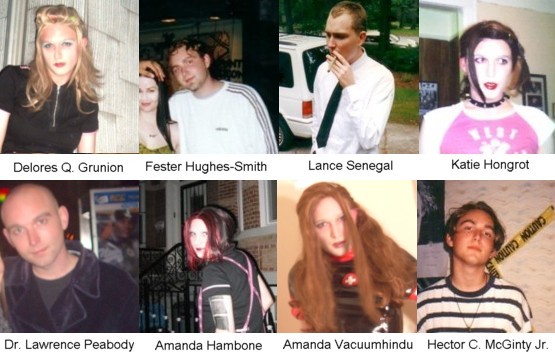

The Agr0Farm TRACTORG® and the

unwillingly abducted person who now

acts as the tractor’s control system.

The countless unexplained disappearances throughout the State of Montsylvania have finally been explained. It seems that AgroFarm, a subsidiary of Daniel Bester Inc., has been abducting countless people and using these unwilling souls as components in their new class of cyborg-controlled tractors.

TRACTORG®, the new line of tractors, freatures human brains which act as control units for the state-of-the-art tilling equipment. In the construction of TRACTORG® models, innocent people are kidnapped off the street or from their homes, then taken to the AgroFarm production facility where they are assimilated.

The painful and horrific process of assimilation involves the amputation of unnecessary limbs, the implantation of interface nodes inot the cictim’s brain, and the eradication of all personality. While the subjects remain aware of the their surroundings, and while they are no doubt capable of feeling great pain and suffereing at their loss of individuality, the people are no longer capable of expressing such things, and thus these emotions are of no consequence to the farmers and agriculturalists who utilize the TRACTORG® technology.

An AgroFarm spokesman reported that while thousands upon thousands of innocent people are suffering horrors beyond comprehension, it is well worth it, because the TRACTORG® models are nearly six percent more efficient than non-cyborg controlled farming equipment.

While the victims’ families have attempted to file a civil suit against AgroFarm’s parent company Daniel Bester Inc., the suit has been dismissed by Circuit Court Judge James Thorax, who by a mere coincidence is also Honorary Vice-President of AgroFarm.

Be sure to check out the whole line of TRACTORG® models when they officially premier at the World Tractor Fair, being held next July at the Actria Falls, Elizabethia Civics Center.